Product News

Improve Sound Absorption and Sound Insulation Performance

Posted by Nick Franks

Lignacite have established a reputation for their extensive range of high-quality commodity and architectural-facing masonry blocks capable of improving acoustic, sound absorption and sound insulation values.

Sound absorption is an extremely effective method of lessening the echo and noise within a space, room or building. Products designed to absorb sound are normally made from soft materials which act to soak up noise as it hits the surface.

However certain blocks manufactured by Lignacite perform considerably better than would be expected for a denser material.

Lignacite | Lignacrete | LignaLITE

Within the Commodity range, Lignacite offer 3 blocks, all able to help improve sound absorption and insulation performance.

Lignacite General Purpose, Standard Fairface, Paint Grade and Lignacrete provide excellent levels of sound insulation between buildings and adjoining rooms. These blocks can also be used in cavity party wall constructions in dwellings, satisfying the specifications for lightweight blockwork in accordance with Approved Document E to the Building Regulations. Full details are available from the Lignacite Technical Library.

Products, such as LignaLITE and Premier from the Lignacite range are effective in reducing reverberated noise in schools, sports facilities, public buildings and conference rooms as well as stairways and other common areas within flats.

The LignaLITE commodity block achieves a very good level of sound absorption across a broad range of frequencies. The block is lightweight and available as Paint Grade. The table below shows a comparison of performance against other material types.

| Material | Sound Absorption Coefficient - a - |

| 1 LignaLITE blocks– no finish | 0.60 |

| Lignacite Premier blocks – cellular & solid blocks | 0.35 |

| Acoustic tiles | 0.4 - 0.8 |

| Brickwork, painted | 0.01 - 0.02 |

| Brickwork, unpainted | 0.02 - 0.05 |

| Carpet, heavy on concrete | 0.3 - 0.6 |

| Carpet, heavy on foam rubber | 0.5 - 0.7 |

| Concrete block, coarse | 0.3 - 0.4 |

| Concrete block, painted | 0.05 - 0.07 |

| Cork sheet, 6mm | 0.1 - 0.2 |

| Fiberboard on battens, 12mm | 0.3 - 0.4 |

| Floor, concrete or terrazzo | 0.02 |

| Floor, linoleum, asphalt, rubber or cork tiles on concrete | 0.03 |

| Mineral wool, 100mm | 0.65 |

| Persons, each | 2.0 - 5.0 |

| Plaster walls | 0.01 - 0.03 |

| Wood wool cement on battens, 25mm | 0.6 - 0.07 |

Facing Masonry Blocks – Premier | Special Shapes

Lignacite’s Premier Facing Masonry range is available in three subtle finishes ‘Natural,’ ‘Textured’ and ‘Planished’ with each finish offering a distinct appearance. The blocks can be used both internally and externally, allowing designers to be creative in the knowledge they are also specifying a durable eco-friendly product.

In addition, tests completed by SRL Technical Services, an independent test laboratory, on the ‘100 solid’ and ‘140mm cellular blocks’ found their sound absorption characteristics to be considerably better than established data for other common masonry materials. **

The results for both blocks achieved a Class D sound absorption rating. Utilising these within a structure allows architects, designers and contractors to demonstrate a significant contribution towards reducing long reverberation times and echoes whilst improving speech intelligibility.

**’Successful recent designs have included fair-faced blockwork (having Class D absorbent finish) from the ground floor up to 3m, in addition to a Class C perforated roof liner. This provides adequate distribution of absorption and diffusion within the listener plane, in addition to an impact resistance finish.’

Quotation taken from the Acoustic Performance Standards for Educational Buildings contained within PSBP 2012.

The Premier block has been successfully used in a number of schools and sports facilities, including the UEA Sports Park in Norwich.

Acoustics – The use of Special Shapes

Lignacite Ltd has many years of experience producing shaped units. We manufacture an extensive range of standard cut, cut and bonded and cast shapes. In addition, special units can be produced to architects' and designers’ specifications.

Whilst our blocks and shapes are produced at the same factory in Brandon differences in colour and finish may occur as a result of the hand-manufacturing processes used to produce shapes. Our technical team are on hand to provide advice during the design stages of a project.

Our Schauer & Haeberle grinding and polishing machine complements our existing cutting and grinding facilities offering a cost-effective way of including sophisticated and subtle details in building designs. Edges can be bevelled, chamfered or rebated and ‘pistol’ blocks can be produced.

Block type, shape and surface differences can be positively exploited and included as part of the intended design features.

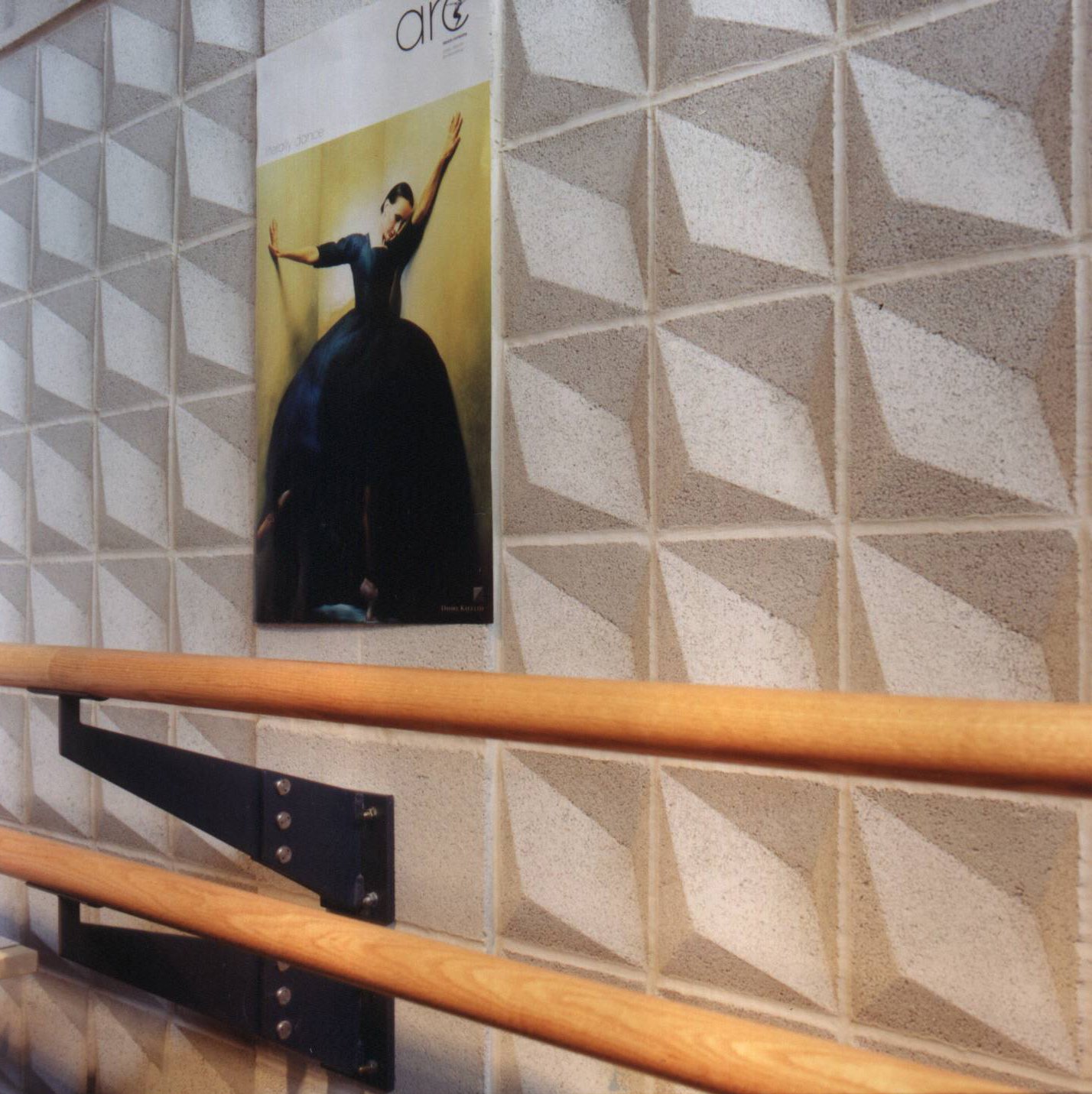

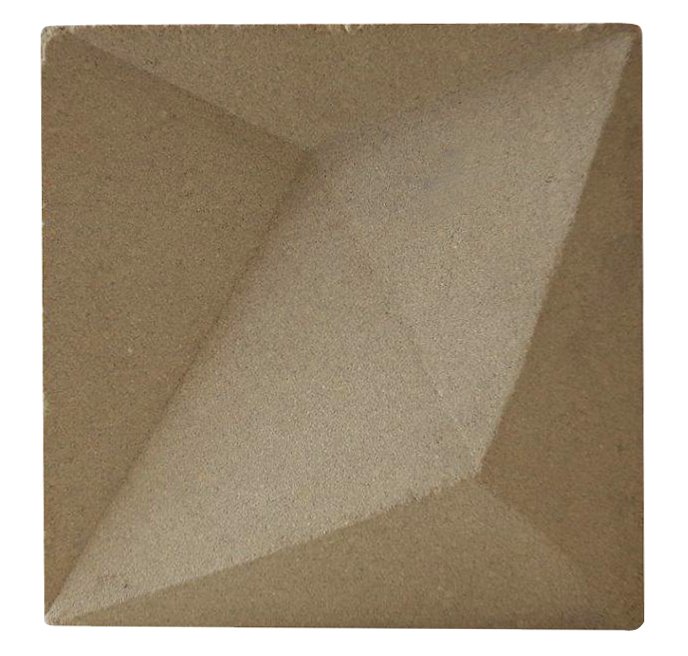

Working in conjunction with the Arts Team @RHWL in 1997, Lignacite developed a multi-faceted block designed to help the dispersal of sound in the new Dance Rehearsal Studios at Sadlers Wells. The blocks were hand-cast in a non-standard block format of 215 x 215mm in the Premier Natural range, Pearl colour.

For further information please visit our concrete blocks page. A full-colour Swatch Guide showing all our block finishes can be requested via our website as well as many other useful documents including a Design Guidance booklet. We offer a CPD on the benefits and uses of concrete masonry. Please contact us for further details on 01842 810678.