Articles

How long do concrete blocks last? The lifespan and durability of CMUs

Posted by Nick Franks

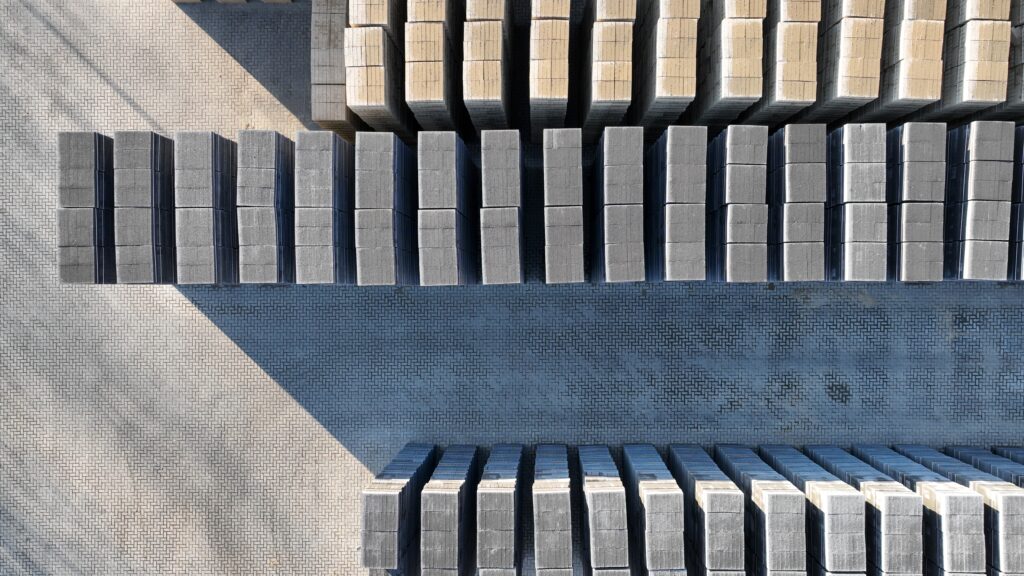

Concrete blocks are a fantastic building material and a favourite in the building industry. This is because they are long-lasting, fire resistant and low maintenance.

But how long exactly does a concrete masonry unit last? Let’s take a little look into their lifespan and the factors that can affect their durability.

How long do concrete blocks last?

If the conditions are right, concrete building blocks have a lifespan of 100 years or more. This makes them a very durable building material.

Indeed, concrete created during the Roman Empire can still be found today, which demonstrates how long-lasting it can be.

However, if conditions are not optimum, concrete blocks could last as few as 50 years.

The impact of longevity on sustainable construction

If kept in the right conditions, the long lifespan of concrete blocks makes them a popular choice for the construction industry. The fact that they need little maintenance and are unlikely to need replacing can also make them a more sustainable construction option over other building materials.

This is because there will be less need for raw materials and energy to create replacements or carry out repairs. The possibility of waste will also be decreased. This can help constructors and designers to manage the carbon footprint of a finished construction.

When do concrete blocks start to deteriorate?

The matter of when concrete blocks deteriorate really depends on the quality of the concrete blocks and local environmental conditions.

Blocks made of lower quality materials are likely to be less durable over time, leading to cracks and reduced compressive strength. Harsh environmental conditions will also take their toll. High humidity, drastic changes in temperature and erosion by fast-moving water can all decrease the lifespan of concrete blocks.

If the quality of the concrete blocks or the conditions in which they are kept or used are not suitable, they can start to deteriorate more quickly, cutting their service life to around 50 years.

Do concrete blocks lose strength over time?

Concrete blocks can lose strength over time. However, if they are made of good quality materials and well maintained, their compressive strength will be sustained for the building's service life.

Moisture can be one of the biggest factors that causes blocks to lose strength. It can affect chemical reactions within the block, which may weaken its structure. If moisture penetrates the block and then freezes, its expansion can also lead to cracks or spalling (when the surface flakes or chips).

Depending on its source, the moisture can introduce contaminants into the concrete block. This can corrode any reinforcing material (such as steel bars) and lead to deterioration.

It can cause efflorescence too. This is when moisture dissolves some of the minerals in concrete. This process leaves chalky white deposits on the concrete block’s surface, which is not only unsightly but could be an indicator of weakness caused by excessive moisture in the building.

What factors affect the lifespan of concrete blocks?

There are many factors that can influence the lifespan of concrete blocks. Here are just a few.

Quality of building materials

The quality of the materials used in forming the concrete blocks has a decided impact on the finished product’s longevity. The quality and content of the cement used in the mix can be particularly influential and could cause shrinkage as the concrete is cured.

Other materials and aggregates need to be of good quality too, and their moisture content taken into consideration. Too much moisture and the concrete block’s strength could be compromised.

Water needs to be pure and free of impurities. The presence of anything in the water could lead to later concrete deterioration, so water supplies should be regularly tested.

Environmental factors

Environmental factors have a huge impact on the durability of concrete blocks.

Abrasion of concrete blocks and wearing of their surface can occur if the blocks are placed in rapidly moving water, for instance.

Freezing and thawing cycles can also have a detrimental effect. This can cause moisture within the concrete blocks to expand and contract, which can lead to cracking and a drop in compressive strength.

Concrete blocks that are protected from extremes of temperature and sealed against moisture will therefore have longer lifespans and remain a sturdy building material.

Carbonation

Carbonation refers to another reaction in the concrete. In this case, the carbon dioxide in the environment reacts with the calcium hydroxide in the concrete block. This creates calcium carbonate and water. This is a slow process that begins on the concrete’s surface before moving inwards. If the concrete block has reinforcing material in it (such as rebar), this reaction could cause the bars to corrode and structural integrity to be lost.

Alkali-silica reaction

Sometimes, concrete blocks can experience an alkali-silica reaction. This is when the aggregates containing silica react with the alkali hydroxides in concrete. This leads to the concrete expanding, resulting in cracking over time.

However, if the concrete block manufacturer uses certain additional materials, this reaction can be reduced or eliminated, protecting the integrity of the block.

Find out more about our durable concrete blocks

If you’re looking for robust and durable blocks for your next building or construction project, you can try out our Block Locator tool to find just the right product for you.

You can also get in touch with our helpful Sales team by calling 01842 778485.