The Whiteley:

Bespoke Concrete blockwork for a unique restoration

When Lyons & Annoot was commissioned to work on the massive regeneration of The Whiteley, it looked to Lignacite to provide concrete blocks that meet the project’s strict weight requirements.

Key Facts

| Location | Queensway in Bayswater, London |

|---|---|

| Sector | Concrete Blocks For Commercial Use, Residential, |

| Lignacite products used | Lignacite, Lignalite 190mm Lightweight, |

| Architect | Foster & Partners |

| Developers | MARK and C C Land |

| Main Contractor | Laing O’Rourke |

| Blockwork Contractor | Lyons & Annoot |

| Expected completion date: | 2023 |

The Project

The Whiteley is an ambitious redevelopment of a Grade II listed former department store, which aims to breathe new life into a well-known structure while protecting its heritage. With a blockwork requirement of around 50,000m2, it is one of the largest packages in London.

The iconic front facade, courtyard and dome of The Whiteley will be restored to their former glory, but their use will be expanded from a purely retail application. When completed, the retail offering will be complemented by destination restaurants as well as a gym, spa and hotel, in addition to 139 highly desirable apartments and townhouses. By diversifying and restoring, the project will rejuvenate the area and give The Whiteley back its sense of self.

To sympathetically restore while also transforming the building’s purpose, the project has imposed strict size and weight requirements when it comes to blockwork. Its location in a built-up area of London also demands blockwork suppliers who are experienced in logistics and timely delivery.

Our Blockwork Solution

To meet the specific needs of this ambitious project, Lignacite is supplying both Lignacite and Lignalite blockwork.

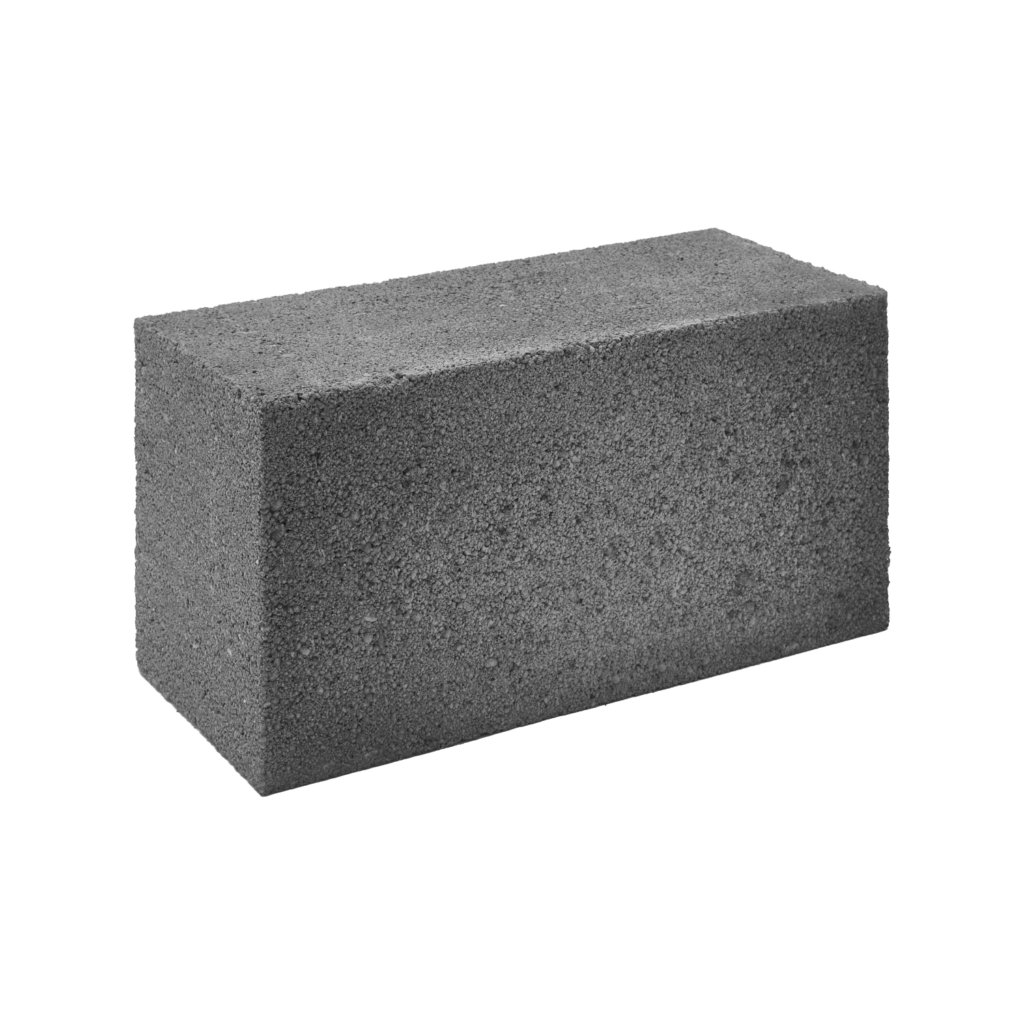

Fine-textured and medium-dense Lignacite blocks are being provided as fair face. With up to four hours of fire resistance for non-load-bearing 140mm blocks and excellent sound insulation of 56dB with an acoustic wall lining, these blocks are ideal for maintaining the safety of the building while also protecting inhabitants and guests from unnecessary noise and sound disturbance as a result of the structure’s mixed-use.

Thanks to their specially formulated mix, Lignacite’s blocks also have reduced density, bringing each block to less than 20kg in weight – an important consideration in a project with strict weight limitations.

The Block

2 products

In addition, Lignacite is also supplying an even lighter product. Lignalite blocks are the lightest in Lignacite’s range, with the 190mm version weighing just 19.1kg. Thanks to their close texture, these blocks combine a relatively low weight with strength, providing a solid background with which to secure fittings. As a result, they can be employed in both load-bearing and non-load-bearing roles.

The good all-round technical performance of the Lignalite blocks is supported by high levels of fire resistance (four hours for 190mm blocks) and sound insulation of 51dB when painted.

The precise requirements of the development led to the need for these blocks in 100mm, 140mm and 190mm sizes. Typically, these blocks are produced by Lignacite in 190mm sizes, but the company’s flexible and proactive approach to manufacturing means that it is able to provide a 140mm version.

Try our Block Selector

Investigate which Lignacite blocks would be best suited for your development by answering a few simple questions.